compression test vs tensile test|Compressive Test: Guide to its Importance and : distributors While compression strength measures a material's ability to withstand compressive forces, tensile strength measures its ability to resist tensile forces. Understanding these properties is . Onlyfans - Weejulietots. 2 years ago. blonde big ass 1 with hot sextape latina sex ass anal on tits big tits fuck onlyfans dildo asian cum blowjob show creampie joi s pussy of video nude and sexy pawg her girl tease - 2 boobs & solo pov 3 riding bj big the bbc masturbation lingerie a in cosplay Show All Tags. Watch 31 weejulietots porn videos.

{plog:ftitle_list}

WEBFrance, Jérôme. 24 contributions de 1985 à 2014. Agrégé d'histoire. - Professeur d'histoire romaine à l'Université Michel de Montaigne-Bordeaux 3 (en 2005) ( Source DataBNF)

The Difference between Tensile Test and Compression Test

In the case of tensile tests, the test machine exerts a tension load or force which pulls tensile test samples apart. In the case of plastics tensile testing, the test sample is pulled apart to .While compression strength measures a material's ability to withstand compressive forces, tensile strength measures its ability to resist tensile forces. Understanding these properties is . Compressive vs. Tensile Testing. While compressive testing evaluates a material’s performance under compression, tensile testing involves the application of a tensile force to a .

October 8, 2024. Compression testing is a fundamental method in materials science and engineering used to determine the behavior of materials under compressive loads. It is .

Tension and Compression Testing

Tensile test vs Compression test.

Both tensile and compressive stresses affect material behavior. The atoms making up the material attempt to resist attempts to either pull them apart or push them closer . The following will introduce you to the difference between tensile testing and compression testing. 1) What is a tensile test? Tensile testing is primarily used to measure how much force is required to break or deform a .Both compression testing and tensile testing are fundamental methods of determining the mechanical properties of materials. They provide data that is crucial for design applications, failure analysis, and quality control.

Compression testing, a key type of mechanical testing, involves applying compressive pressure to a material and assessing its response. Tensile testing and compression testing are both crucial in determining a material’s .

The main difference between tensile stress and compressive stress is the type of force applied and how the material deforms as a response. With tensile stress, the force stretches and elongates the material, whereas . For many materials, Young’s Modulus is the same when the material is under tension and compression. There are some important exceptions. Concrete and stone can undergo compressive stresses but fail . Tensile test vs Compression test. A compression test requires a higher capacity machine than tensile test due to the fact that compressive strength of any material is higher than its tensile strength. Moreover, in compresion test cross-section area of the material increases as the loading propagates which requires more load for any subsequent .

Compression Strength vs. Tensile Strength . Testing Method: Compression tests involve applying a compressive force until failure or a specified deformation is reached. Tensile tests involve applying a pulling force until failure or a specified elongation is reached. Further Detail. These values can be found by plotting the graph of tensile stress vs. strain. The data required to plot the graph is obtained performing a tensile test. The plot of the graph of tensile stress vs. strain is linear up to a certain value of tensile stress, and thereafter it deviates. The Hook’s law is valid only up to that value.

moisture meter daraz

Measuring the compressive strength of a steel drum. In mechanics, compressive strength (or compression strength) is the capacity of a material or structure to withstand loads tending to reduce size (compression).It is opposed to tensile strength which withstands loads tending to elongate, resisting tension (being pulled apart). In the study of strength of materials, .

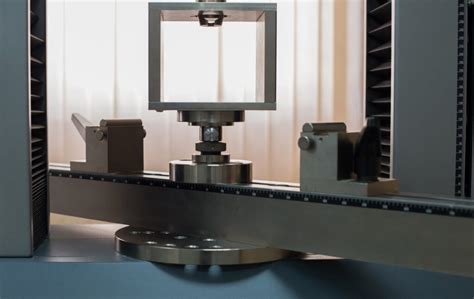

A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load. A typical machine for compression tests consists of a load cell, a crosshead(s), compression test tools, electronics, and a drive system.It is controlled by testing software used to define .Method A is based on the increase in tensile stress during load application. In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this corresponds to 10000 and 100000 psi/min).; However, it is clearly stated in ASTM E8 and ASTM E8M that these specifications and method do not .This pulling stress is called tensile stress. Strain is what results from this stress. Strain, ε, is defined as the change in length divided by the original length, ε = Δ I / I o. Before we proceed further with stress and strain, let's define some other types of stress.Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .

In the compression test, a standardized specimen is loaded under compressive stress until it breaks or until a first crack appears. The testing of materials under compressive stress is carried out in the so-called compression test.Standardized round specimens are used, which are much thicker than tensile specimens.The maximum height of the sample is twice . A tensile test is crucial to accurately determining these strengths. In this regard, Young’s modulus measures the degree of plastic deformation of a material under lengthwise tension or compression. Young’s modulus is another way of calculating the degree of deformation of a material under lengthwise tension or compression.

Regarding testing material factors of PEM ® self-clinching fasteners, our engineers call upon two key testing methods: push-out testing (a variation of a compression test) and tensile testing. These two methods work hand in hand, with the push-out testing method measuring the strength of the self-clinching feature and the tensile test .Tension/compression testing machines. Verification and calibration of the force-measuring system: BS EN ISO 7622-2:1996: This standard covers steel cord conveyor belts. Longitudinal traction test. Measurement of tensile strength. BS EN ISO 8491:2004: This standard covers metallic materials. Tube (in full section). Video 1: Tensile testing of annealed Cu sample (video and evolving nominal stress-strain plot) This page titled 5.5: Tensile Testing - Practical Basics is shared under a CC BY-NC-SA license and was authored, remixed, and/or curated by Dissemination of IT for the Promotion of Materials Science (DoITPoMS) via source content that was edited to the .

Tensile testing is a type of mechanical testing performed on universal testing machines that determines the tensile properties of materials and products. . Instron's 6800 Series systems are available in capacity ranges up to 300 kN .

Tensile and Compression testing is the generic name for many types of tests such as pull test, tension test, load resistance test, and many more. This assessment usually occurs during the design verification testing stage so .

What is compression testing and how is it used to determine how a product or material reacts when it is compressed? . although mostly associated with tensile testing, may have compressive analogs) and compressive strength. Compression testing can be .Shown below is a graph of a tensile test for a common steel threaded rod, providing a good example of a general metal tensile test. The units of engineering stress are ksi , which stands for a thousand pounds per square inch.

Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum .Compression testing like tensile testing also has the advantage of a straightforward process to determine properties directly from the stress-strain curves. Some of the disadvantages the technique contains are its difficulties with sample preparation. Samples have to be cut to strict specifications and the planes of the sample have to be void .The prone knee bending test is a neural tension test used to stress the femoral nerve and the mid lumbar (L2-L4) nerve roots. The femoral nerve tension test is used to screen for sensitivity to stretch soft tissue at the dorsal aspect of the leg, possibly related to root impingements. Clinically Relevant Anatomy [edit | edit source] The curve is obtained in the so-called tensile test. The test consists of loading a specimen and subjecting it to a gradually increasing tensile load. . The opposite of tension is compression .

A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the tensile strength and deformation behavior until break.. A typical tensile testing machine consists of a load cell, crosshead, extensometer, specimen grips, electronics and a drive system.No, the Yield strength for compression test and tensile test will be different for AA-7075. The possible reason for this is .. when we compress the material the dislocation density increases which .

Ultimate Tensile Stress (UTS) and Ductility. It may be noted at this point that it is common during tensile testing to identify a “strength”, in the form of an “ultimate tensile stress” (UTS). This is usually taken to be the peak on the nominal stress v. nominal strain plot, which corresponds to the onset of necking.The design of this machine allows analyzing data from various tests conducted, such as compression, tension, shear, bending, and other loads. . One of the most significant points to note while comparing Universal Testing Machines vs Tensile Testing Machines is their differences in applications and uses.

Tensile testing and compression testing are both crucial in determining a material’s ability to withstand real-world conditions it’s designed for. A compression test is a common method used in this process, and multiple compression tests can provide even more insight into a material’s strength and durability.

Tensile Test vs. Compression Test: Wh

Veículo oficial para divulgação de atos administrativos intern.

compression test vs tensile test|Compressive Test: Guide to its Importance and